Commercial Solutions for Heavy Construction Equipment

Managing and maintaining heavy construction equipment can be very challenging when your organization is not proactive in your trucks’ maintenance activities. You can rely on Universal Fuel Polishing & Tank Services’ commercial solutions for heavy construction equipment. We have helped many fleet managers, heavy truck operators, and industrial sites that rely on equipment run by diesel make the most of their annual maintenance cost allocation. We offer top-tier commercial fleet solutions for all your diesel needs.

At Universal Fuel Polishing & Tank Services, we also offer a variety of treatments and products for different kinds of fuel, mainly diesel, biodiesel, ethanol, and more. Our heavy construction equipment solutions help greatly in ensuring superior and efficient performance. We provide periodic and annual servicing so that you can take out the guesswork from your maintenance activities, including:

- Fuel Testing (ASTM, ISO, NFPA) Standards

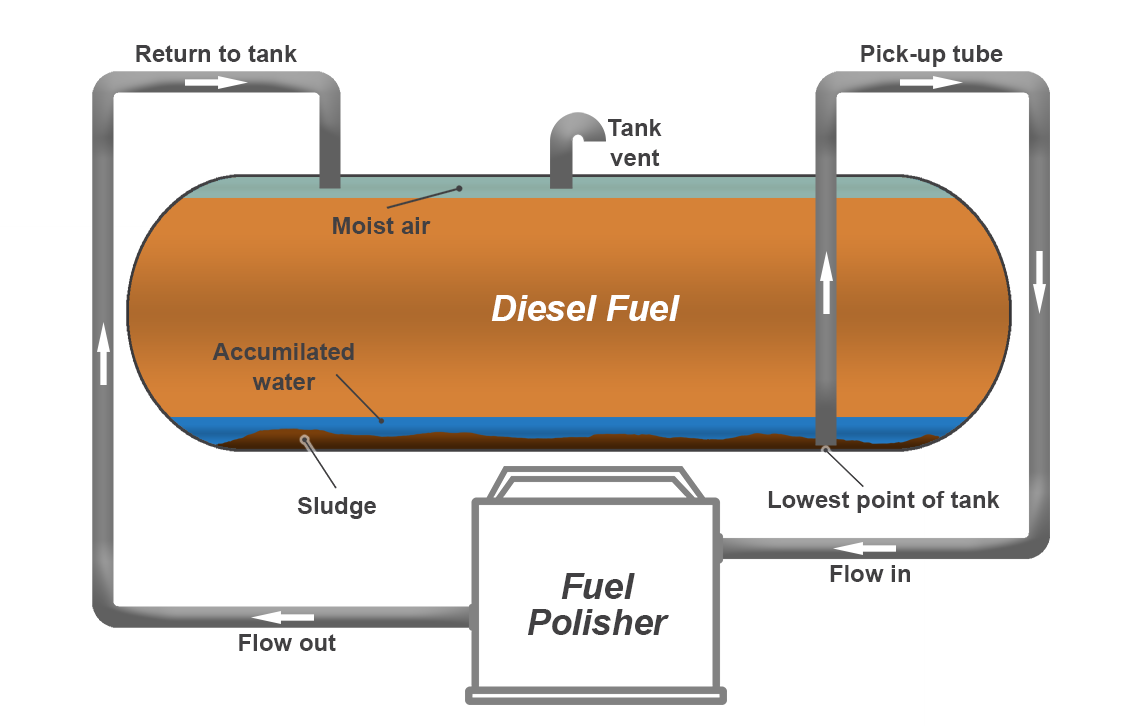

- Fuel Polishing/Filtration

- Fuel Tank Cleaning

- Total Fuel Maintenance Programs

We bring with us our proprietary equipment and specialized skill due to our years of experience. Over the years, Universal Fuel Polishing & Tank Services has gained a reputation as the most trusted company in professional fuel cleaning and testing services in the Rocky Mountain Region. Our fuel tech experts will ensure your heavy trucks and equipment always run and are in good condition, as they only use high-quality diesel fuel.

You can be confident that we will take care of everything you need. We help you plan periodic maintenance and generate reports to help you understand the condition of your heavy construction equipment, including your tanks and stored fuel.

Contact us at Universal Fuel Polishing & Tank Services in Denver, CO, and we will be glad to provide custom services based on your needs. Let us help you prolong the life of your heavy construction equipment through our professional fuel cleaning. We also help you comply with recommendations by the JCAHO, NFPA, and ISO standards. We go above and beyond diesel fuel tank cleaning to help you make the most of your diesel fuel. Reach out to one of our fuel experts today to schedule a site visit and detailed fuel analysis.

Challenges of Heavy Construction Equipment Operators

1. Driver shortages.

This has been a challenge for fleet managers as the shortage of delivery drivers went up in 2022. The demand for freight transport goes up as the number of new driver applicants festers. Recruiting incompetent drivers can also lead to security concerns and the need for driver training.

2. Use of technology.

Innovation can aid in the surveillance of driver answers and safety checks. Since such systems are useful, they add a whole other layer of ambiguity to service.

3. Rising fuel prices.

Depending on the fleet vehicle types, some plants need to allocate more resources due to high fuel costs. Even minor changes in diesel prices can have a massive effect on the company's financial break. Maintenance teams must stay on top of reports of fluctuating fuel usage, looking for issues that can be fixed.

4. Environmental controls.

Fleet managers have a mandate to meet as well as pressure to phase out the use of

combustion engines as extreme weather patterns have brought up the issue of climate change and led to new clean air standards being implemented around the world.

5. Growing popularity of electric and hybrid vehicles.

Electric vehicles have an estimated increase in inflection points from around 2035-2040. The global expansion of manufacturing plants is also on the rise. Information systems can help determine charging costs, savings, and the impact on the bottom line.

6. Route optimization.

Specific apps are designed to be helpful for dispatching service technicians to keep track of fleet vehicles, identify the best vehicle to dispatch for emergencies, and calculate the best route. This GPS-centric data is useful for the fleet manager and maintenance team in monitoring vehicles and pinpointing climate changes that lead to unexpected maintenance needs.

7. Driver behavior.

There is a high connection between operator behavior and system requirements. Reports showcasing bad driving, excessive idling, inaccurate shifting, or disabling safety controls can all be used to improve preparation and encourage improvement since data changes the discussion from anecdotal and speculative to realization.

8. Autonomous vehicles.

While public opinion regarding the use of public highways stays divided, increasing evidence indicates that automated vehicles will comprise a safer and more efficient modeling approach in the future.

9. Security

Technicians must not only scrutinize and ensure that backups and safeguards are in place. Teams will be part of the major line of defense to ensure safe travel and car use in plants, just like fleets become independent and digitally driven. They must also regulate the technologies involved in fleet operation, from dispatch to possible effects on brake fluid balances.

Universal Fuel Polishing & Tank Services of Denver, CO - At Your Service!

Universal Fuel Polishing & Tank Services of Denver at Your Service

If it runs on Diesel Fuel, we can help you!

All Rights Reserved | Universal Fuel Polishing & Tank Services | Designed by Lingows Media