Diesel fuel is a critical component of many industries, from transportation and construction to agriculture and manufacturing. However, diesel fuel is not immune to contamination, which can lead to significant problems and costs. One way to prevent contamination and ensure the proper functioning of diesel-powered equipment is through diesel fuel polishing. In this blog post, we'll explore five key reasons why diesel fuel polishing should be part of your maintenance routine.

1. Contamination Prevention

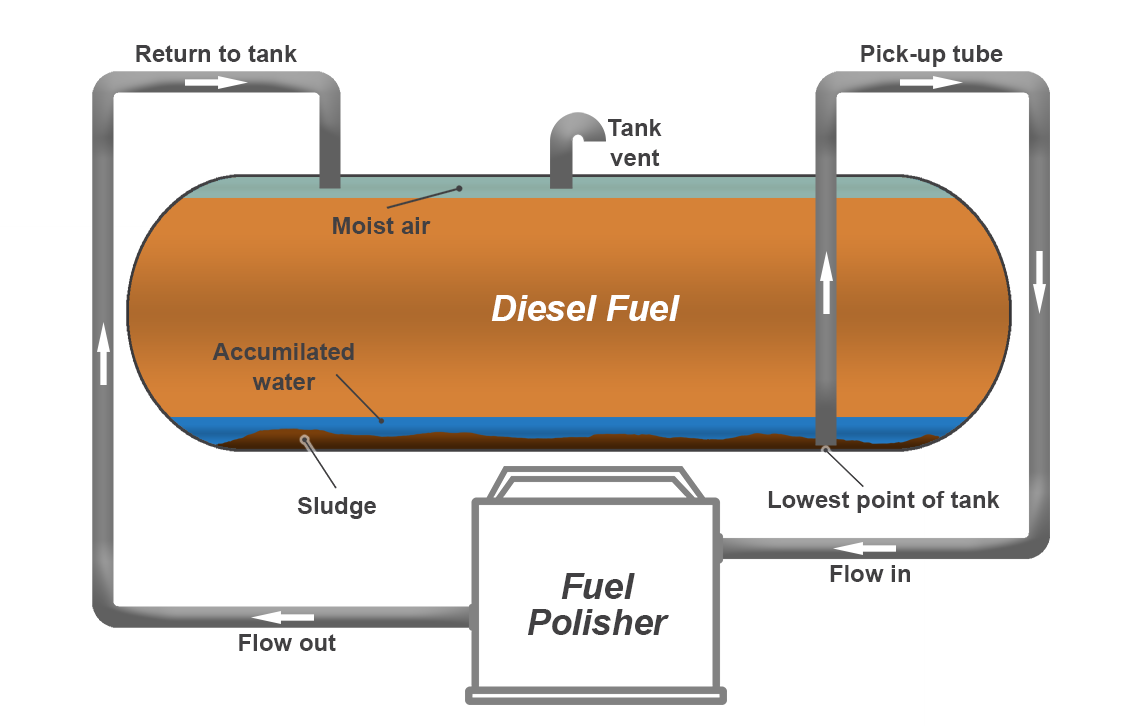

One of the primary reasons to include diesel fuel polishing in your maintenance routine is to prevent contamination. Over time, diesel fuel can become contaminated with water, dirt, and other contaminants, which can lead to engine problems, decreased fuel efficiency, and increased maintenance costs. By regularly polishing your diesel fuel, you can remove contaminants and ensure that your fuel remains clean and usable.

2. Extended Equipment Life

Another key benefit of diesel fuel polishing is extended equipment life. When diesel fuel becomes contaminated, it can cause damage to engine components, such as fuel injectors, pumps, and filters. This can lead to decreased engine performance and increased maintenance costs. By regularly polishing your diesel fuel, you can extend the life of your equipment by ensuring that it is running on clean fuel and preventing damage caused by contaminated fuel.

3. Increased Fuel Efficiency

Clean diesel fuel is essential for maintaining fuel efficiency, which is critical for many industries, including transportation and construction. When fuel becomes contaminated, it can clog filters and reduce fuel flow to the engine, leading to decreased fuel efficiency and increased fuel consumption. By regularly polishing your diesel fuel, you can ensure that your equipment is running on clean fuel, leading to increased fuel efficiency and cost savings.

4. Cost Savings

In addition to increased fuel efficiency, diesel fuel polishing can lead to significant cost savings over time. By preventing contamination and maintaining clean fuel, you can reduce maintenance costs associated with engine damage caused by contaminated fuel. Additionally, increased fuel efficiency can result in cost savings associated with lower fuel consumption.

5. Regulatory Compliance

Finally, diesel fuel polishing can help ensure compliance with regulatory requirements. Many industries are subject to regulations regarding the use and disposal of diesel fuel, and failure to comply with these regulations can result in significant fines and penalties. By regularly polishing your diesel fuel, you can ensure that your fuel meets regulatory requirements and avoid costly penalties.

Conclusion

Diesel fuel is a critical component of many industries, and ensuring that it remains clean and usable is essential for maintaining equipment performance and preventing costly problems. By including diesel fuel polishing in your maintenance routine, you can prevent contamination, extend equipment life, increase fuel efficiency, achieve cost savings, and ensure regulatory compliance. As such, diesel fuel polishing should be a key consideration for anyone responsible for managing diesel-powered equipment.

Write a Comment