Commercial Diesel Solutions for Data Centers

As technology grows and the demand for high-speed data transmission increases, reliability is what people pay for. They want to work with data centers that can provide them with the security and stability they need, which means that powering down, even for a few minutes, would cause a large deficit in revenue.

Data centers play a vital role in the everyday lives of many people. They are responsible for providing services that allow many businesses to operate, and to do so, they need reliable power sources, including backups for emergencies.

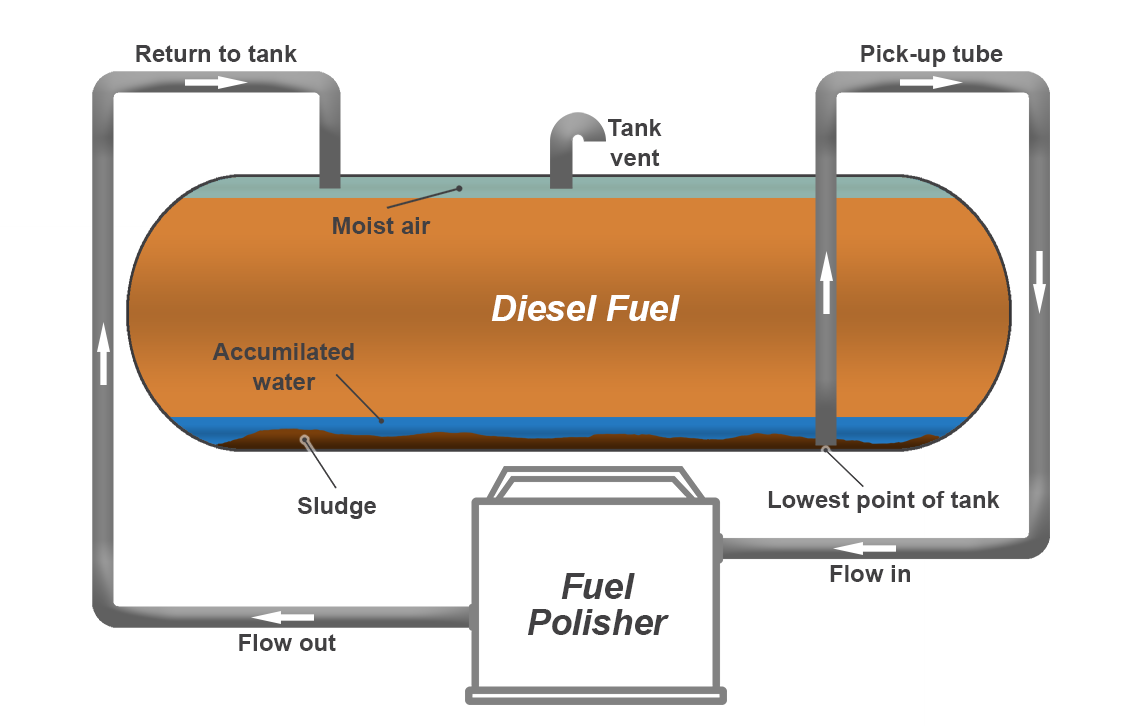

The vast majority of data centers rely on diesel-powered generators as their emergency power source. These generators are always on standby, along with diesel fuel stored in tanks around the site for efficient operation. But just like any other fuel, diesel fuel can go bad if stored long-term without proper cleaning and maintenance.

Diesel fuel can easily be contaminated by both internal and external factors. External pollutants and varying temperatures can speed up fuel degradation, leading to chemical reactions that create gum and sludge in the fuel. When used, contaminated fuel can affect a generator’s ability to function and, in the worst cases, cause corrosion that damages the generator entirely.

On average, diesel fuel in storage tanks can last around six months, and while fuel degradation is inevitable, it can be delayed. Regular tank cleaning and maintenance, along with fuel treatment, can help prolong the life of diesel fuel for up to 12 months. This gives data centers the best bang for their buck, allowing them to use the diesel fuel they have stored for longer periods of time.

Our team at Universal Fuel Polishing & Tank Services provides top-tier cleaning and maintenance services for data centers. We will help you prolong the life of your diesel fuel, and you can be confident that we will take care of everything you need – from planning periodic maintenance to generating reports that help you understand the condition of your tanks and stored fuel.

Universal Fuel Polishing & Tank Services is your partner in keeping your diesel tanks in good condition while complying with recommendations by the JCAHO, NFPA, and ISO standards. We go above and beyond diesel fuel tank cleaning to help you make the most of your diesel fuel. Get in touch with one of our fuel experts today to schedule a site visit.

Universal Fuel Polishing & Tank Services of Denver, CO - At Your Service!

Universal Fuel Polishing & Tank Services of Denver at Your Service

If it runs on Diesel Fuel, we can help you!

All Rights Reserved | Universal Fuel Polishing & Tank Services | Designed by Lingows Media