Fuel Filtration System

Here at Universal Fuel Polishing & Tank Services, we understand the importance of having clean and efficient fuel, which is why we offer complete fuel polishing, filtration, and purification for a variety of different industries. Our approach to fuel filtration, polishing, and reclaiming fuel is second to none. Based in Colorado, we provide fuel filtration, polishing, and generator services for all of Colorado and Wyoming. We are the largest in our space and currently process more fuel than any company in the Rocky Mountain Region.

We test all fuel to

ASTM and

ISO standards before and after. We offer our services to most facilities in the

Rocky Mountain Region — Data Centers, the Department of Defense, the Department of Transportation, Insurance Companies, Life Care Centers, Municipalities, Radio Stations, and Telecommunication companies.

Over the past few years, the economic demands for cheaper and more abundant fuel have placed a lot of pressure on the oil industry. And this has resulted in lower quality and more readily adulterated fuels. You may not be able to count on certain standards of fuel quality anymore, and this is precisely why fuel polishing and generator services are a wise investment. You can rely on Universal Fuel Polishing & Tank Services to be in your corner when it comes to filtering your fuel to ensure its optimum performance. Don't hesitate to contact one of our tech experts to schedule a detailed fuel analysis.

We are your partner in maintaining the competency and longevity of your system.

Why Fuel Filtration is Crucial?

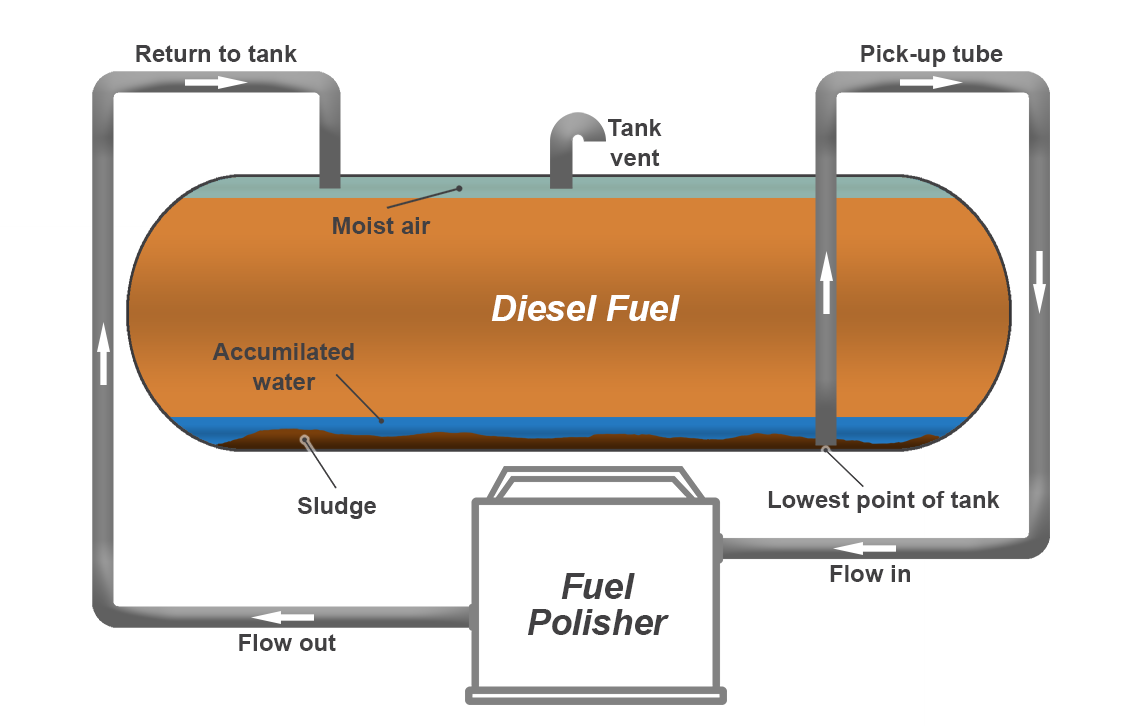

Regardless of the system that you’re putting fuel into, from small truck engines to large industrial power generators, it’s crucial that your fuel is clean. Running your engine system on dirty fuel can lead to buildup, sludge, bacteria, fungus, and other sediments. This buildup can cause serious damage to your engine, costing you a fortune in the long run.

At Universal Fuel Polishing & Tank Services, we can run your entire fuel supply through our advanced filtration process, extracting all the impurities before putting them back into your storage system for safekeeping.

Expertise in Fuel Filtration systems

With Universal Fuel Polishing & Tank Services, you can expect the safest and most professional team in the industry. Our systems are built to adhere to the strictest standards. Also, they are continually cleaned and inspected to eliminate cross-contamination. More importantly, our fuel polishing and generator services, in most cases, do not disrupt service.

For annual on-site fuel testing and maintenance, we offer documentation services, including taking and storing images in compliance with

JCAHO,

NFPA,

and

ISO standards. We service the most critical facilities in the

Rocky Mountain Region, including Insurance Companies, Municipalities, Data Centers, Life Care Centers, the Department of Transportation, the Department of Defense, Radio Stations, and Telecommunication companies, to name a few.

State-of-the-Art Fuel Maintenance

At Universal Fuel Polishing & Tank Services, our fuel maintenance services on diesel fuel tanks involve fuel filtration. With this, you can reap these benefits:

- Better fuel economy

- Higher power reliability

- Longer life engine systems

- Much Improved safety

- Short-term and long-term savings

We at Universal Fuel Polishing & Tank Services are your partner in compliance with recommendations according to JCAHO, NFPA, and ISO standards. We are the leading emergency backup generator fuel tank cleaning company. We go above and beyond for diesel fuel tank cleaning. We work directly with chemists, contractors, engineers, and equipment manufacturers and offer the best maintenance and materials plans for your facility fuel system. We offer periodic and annual service contracts for diesel fuel tank maintenance schedules. Talk to one of our fuel experts today to schedule a site visit and detailed analysis.

Universal Fuel Polishing & Tank Services of Denver, CO — At Your Service!

Universal Fuel Polishing & Tank Services of Denver at Your Service

If it runs on Diesel Fuel, we can help you!

All Rights Reserved | Universal Fuel Polishing & Tank Services | Designed by Lingows Media