Building Generator Maintenance

Every industry that requires backup generators relies on diesel fuel because it is a more cost-effective option for emergency preparedness. Therefore, maintaining the quality of stored diesel fuel is highly important to make sure all equipment, machinery, and backup generators have a reliable power source. Also, the storage tank must be well maintained to avoid wasting any stored fuel. Whether you are a fuel distributor, a data center, or a healthcare facility, you can trust Universal Fuel Polishing & Tank Services to help manage your fuel and fuel tank systems efficiently.

With our expertise and years of experience, we help industries be prepared in the event of a power failure by ensuring that their emergency backup generators are always ready. Our commercial solutions include fuel testing, cleaning, and polishing. We also provide professional fuel tank cleaning services using state-of-the-art and proprietary equipment. We eliminate any potential problems regarding your fuel and tank systems before they turn into major issues and cause your engine systems to fail.

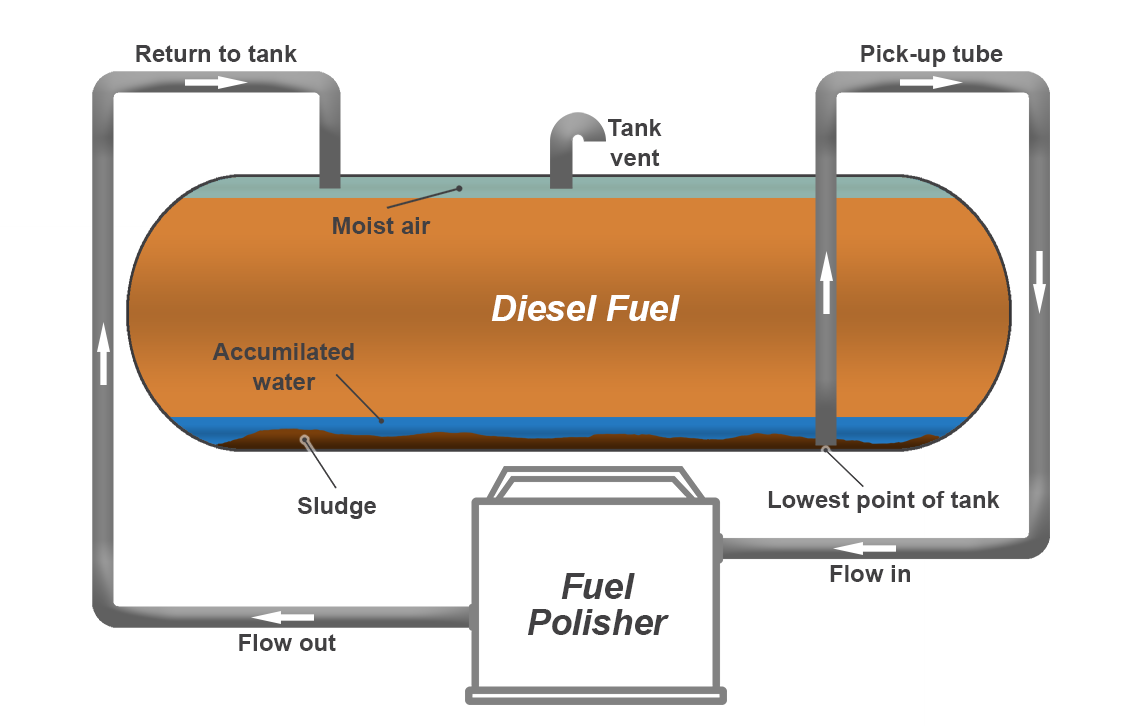

The longer diesel fuel is stored, the more its quality deteriorates because of the presence of fuel contaminants, which are a result of oxidation. When fuel is contaminated, it causes engine failure. Similarly, fuel tanks with high capacity, which most industries use, require periodic draining and fresh fuel replacement. However, at Universal Fuel Polishing & Tank Services, we do fuel polishing in lieu of draining to prevent stoppage in your operations. We strongly recommend fuel polishing for us to efficiently clean your stored fuel. This will also help you to be in compliance with the standards mandated by the state and agencies when it comes to keeping fuel in “good condition”.

We are the leading fuel maintenance and fuel tank cleaning company that serves Colorado and Wyoming. You can choose from our annual and periodic service contracts as part of your scheduled maintenance program. Our fuel technology experts will take the guesswork out of your maintenance services. We handle everything—we give you the data and perform quick tests on your fuel. We do this to assure you that your fuel and engine systems are operating at optimal capacity.

Contact us today at Universal Fuel Polishing & Tank Services to schedule an on-site visit and detailed fuel analysis as part of your building generator maintenance.

State-of-the-Art Fuel Tank Cleaning

At Universal Fuel Polishing & Tank Services, we begin the process by assessing the sub-base and above, below ground fuel tanks. Then we keep complete records of every tank, including tech notes and images. When a fuel tank cleaning service is performed on your system, complete documentation from our technician is provided before the job is considered complete.

Based in Denver, CO, we use high-quality products that are tailored to provide solutions for all your diesel needs. We can help you take care of the following problems:

- Dark or thick exhaust smoke

- Frequent engine stalls

- Low rpm, even at full throttle

- Rough idle

- Reduction in fuel economy

- Water contaminated diesel

- Unusual fuel odor

- Water in your fuel

- Unexplained sediment or contaminant

- Clogged fuel filters or lines

- Fuel system fouling

We are your partner in keeping your diesel tanks in good condition while complying with recommendations by the JCAHO, NFPA, and ISO standards. We go above and beyond diesel fuel tank cleaning to help you make the most of your diesel fuel. You can be confident that we will take care of everything – from planning your maintenance periodically to generating reports that will tell you everything you need about maintaining your building’s generator.

Get in touch with one of our fuel experts today to schedule a site visit.

Universal Fuel Polishing & Tank Services of Denver, CO - At Your Service!

Universal Fuel Polishing & Tank Services of Denver at Your Service

If it runs on Diesel Fuel, we can help you!

All Rights Reserved | Universal Fuel Polishing & Tank Services | Designed by Lingows Media