Diesel Fuel Contamination

Effective fuel storage is key to making sure that any organization does not have to stop its operations, even during emergencies. And yet, most organizations neglect the idea of keeping stored fuel in good condition. After purchasing diesel fuel and keeping it in inventory inside storage tanks, it is important that it is viable for use to power up generators and other emergency management systems. What you want to avoid is diesel fuel contamination.

At Universal Fuel Polishing & Tank Services, our fuel maintenance plans prevent diesel contamination, so you can protect your investment. Our experience and expertise in handling fuel assure you that you can count on your stored diesel fuel, especially when you need it the most, to run your business. We help you maintain the viability and quality of your diesel fuel through state-of-the-art fuel cleaning, filtering, and testing. Plus, we provide documentation and images to keep a record of the health of your fuel, so you can easily comply with requirements set by authorized agencies.

We aim to take out the guesswork in your system and worry that your equipment may fail to work due to contaminated diesel fuel. And even before you get to that “failure equipment” point, here are three things you need to look out for as diesel fuel contamination symptoms.

- Having to frequently replace fuel filters

- Appearance of diesel bugs or sludge in your fuel

- Fuel Tank corrosion due to rust

Our fuel experts at Universal Fuel Polishing & Tank Services want to eliminate these issues at once. Contact us today and schedule a detailed fuel analysis.

Effects of Diesel Fuel Contamination

Proper management and prevention of fuel contamination are highly important, especially if your business operations highly rely on diesel fuel. If not done properly, here are the effects of diesel fuel contamination.

- Blocked filters

- Damaged pumps

- Engine issues

- Corrosion of fuel system

- Fuel inefficiency

Don't wait for the worst to come. Avoid diesel fuel contamination at all costs. Book an appointment with one of our fuel experts at Universal Fuel Polishing & Tank Services and request a detailed analysis.

Types of Diesel Fuel Contamination

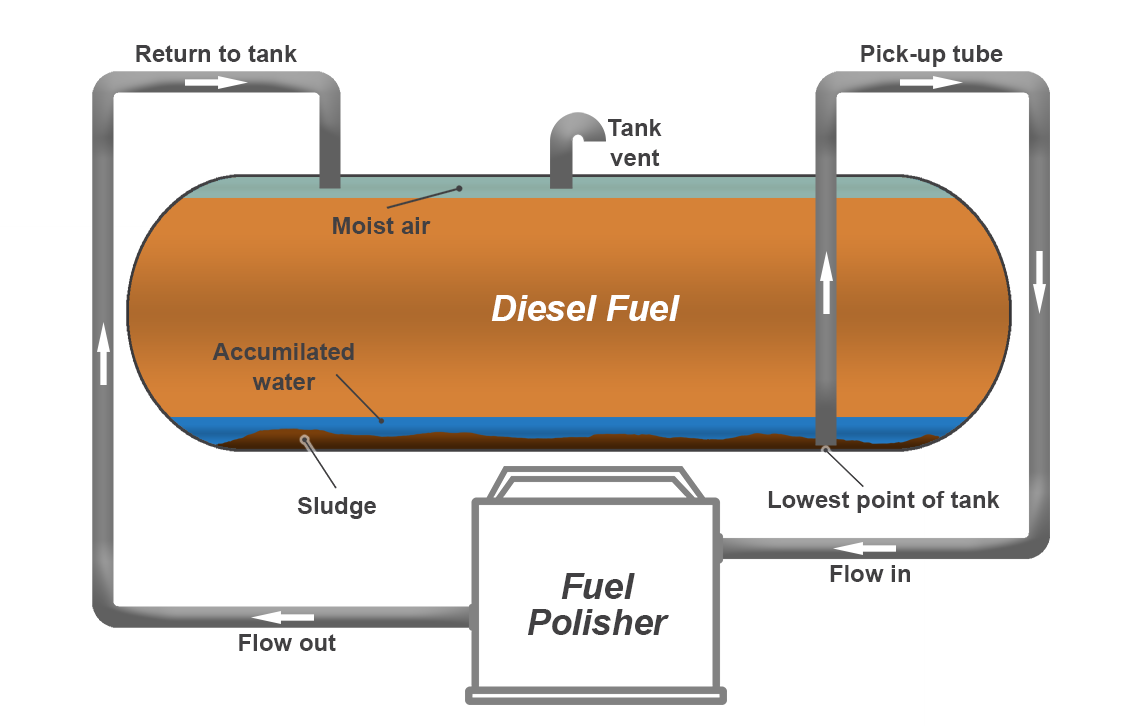

There are three basic contaminants when it comes to advanced fuels. These are classified into three categories that make up most of the contaminants that are usually found in fuel and in oil.

- Organic debris. These are products of fuel breakdown, microbial products, and the waste products of fuel deterioration.

- Inorganic debris. These include sand, dust, and rust.

- Water

When it comes to “organic debris,” the most common microbial contamination is known as diesel algae or fungus. However, it has more to do with lacquers, petroleum gums, and varnishes than with “algae.” That’s because algae need light for it to grow, so they cannot grow inside storage tanks. Other types of microbes, such as bacteria, fungi, and molds, are more likely to grow and cause fuel contamination.

State-of-the-Art Fuel Maintenance

At Universal Fuel Polishing & Tank Services, our fuel maintenance services involve fuel filtering, polishing, and testing. We want you to experience:

- Better fuel economy

- Higher power reliability

- Longer life engine system

- Much improved safety

- Short-term and long-term savings

We at Universal Fuel Polishing & Tank Services are your partner in compliance with the recommendations by the JCAHO, NFPA, and ISO standards. We are the leading emergency backup generator fuel tank cleaning company. We go above and beyond with diesel fuel tank cleaning. We work directly with chemists, contractors, engineers, and equipment manufacturers and offer the best maintenance and materials plans for your facility fuel system. We offer annual and periodic service contracts for diesel fuel tank maintenance. Talk to one of our fuel experts today to schedule a site visit and detailed analysis.

Universal Fuel Polishing & Tank Services of Denver, CO - At Your Service!

Universal Fuel Polishing & Tank Services of Denver at Your Service

If it runs on Diesel Fuel, we can help you!

All Rights Reserved | Universal Fuel Polishing & Tank Services | Designed by Lingows Media