A Proactive Approach to Fuel system maintenance

Dealing with fuel concerns is a universal issue. With Universal Fuel Polishing & Tank Services, you can be assured of the proper function of your fuel tank and its stored fuel when you need it. We do proper testing, cleaning, and fuel system maintenance. At Universal Fuel Polishing & Tank Services, we begin by assessing your sub-base and above, below-ground fuel tanks. When service is performed on your fuel system, we provide complete tech notes and images of every tank before the job is considered complete. You can use these records for your documentation in compliance with the rules and regulations.

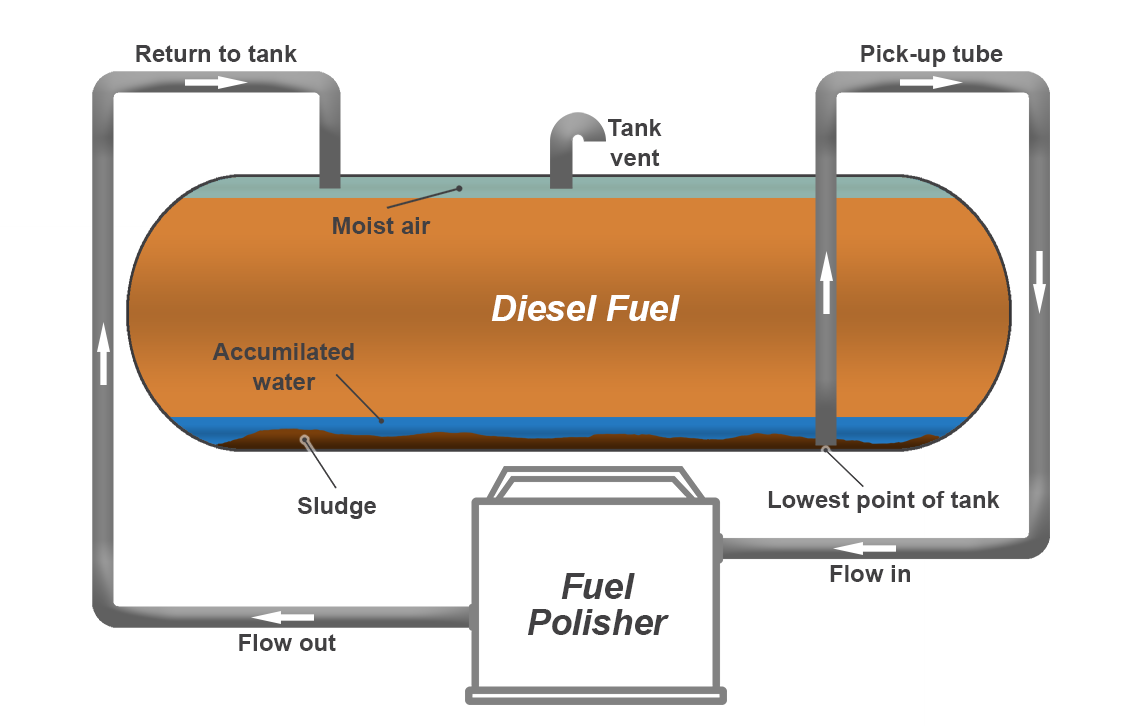

We at Universal Fuel Polishing & Tank Services are your partner in compliance. Our techs are trained in a

proprietary state-of-the-art tank cleaning and polishing system. Emergency generator fuel storage tanks are cleaned, and the fuel is polished with no system downtime or use of a vacuum truck. The process does not require emptying the fuel tank prior to the cleaning, and the tank remains in operation while Universal Fuel Polishing & Tank Services techs complete the Denver emergency generator fuel tank cleaning. If you are looking for

better engine performance and efficiency, schedule a professional fuel tank cleaning by Universal Fuel Polishing & Tank Services.

We offer services and documentation around JCAHO, NFPA, and ISO recommendations for annual fuel testing and fuel maintenance at sites. We offer our services to most facilities in the Rocky Mountain Region — Data Centers, the Department of Defense, the Department of Transportation, Insurance Companies, Life Care Centers, Municipalities, Radio Stations, and Telecommunication companies. We work collaboratively with our customers to develop a comprehensive fuel management strategy with a regularized maintenance and testing program. At Universal Fuel Polishing & Tank Services, we won’t let you overlook the lifeblood of your emergency power system!

Why Fuel Tank Maintenance is Crucial?

Having scheduled preventative maintenance on your fuel tank is vital to successfully store diesel fuel. It is necessary to make sure the fuel you store does not go “bad,” which leads to wasting your investment. In addition, you prevent “bad fuel” from going into your power system or equipment. That is why keeping your diesel fuel tank well-maintained ensures optimal performance while it prevents any costly damage to your equipment.

Benefits of Having Scheduled Fuel Tank Maintenance

- Better fuel economy

- Higher power reliability

- Longer life engine system

- Much Improved safety

- Reduced power downtime

- Reduced injector failures

- Reduced smoke for easy compliance with emission regulations

- Reduced downtime and operational costs

- Short-term and long-term savings

Universal Fuel Polishing & Tank Services specialize in professional diesel fuel tank cleaning. We offer periodic and annual service contracts for diesel fuel tank maintenance schedules. Talk to one of our fuel experts today to schedule a site visit and detailed analysis.

Fuel System Preventative Maintenance for Better Performance

If you are looking for better engine performance and efficiency, book a professional cleaning for your fuel tank. Here at Universal Fuel Polishing & Tank Services, we specialize in keeping your tanks and equipment free of the debris and buildup that can cause damage to components and reduce your output.

If you are concerned about the quality and cleanliness of your fuel tank or storage system, especially if it has been sitting unused for a while, you can count on us to get things spic and span again.

Investing in a thorough tank cleaning saves you a lot of time, money, and hassle in the long run.

We pay attention to even the smallest details, getting every inch of your fuel tank clean and free of sludge, algae, sediment, and water, leaving you with a fresh and smoothly running system.

Universal Fuel Polishing & Tank Services of Denver, CO — At Your Service!