Data centers are crucial for the functioning of our digital world. They store, process, and distribute the vast amounts of data that we rely on every day. However, these facilities are only as reliable as the equipment they use, and the fuel that powers that equipment. Fuel quality is an essential aspect of data center operation, and fuel polishing is a critical component of ensuring that fuel remains clean and usable.

What is a Data Center?

A data center is a facility that houses computer systems and associated components, such as telecommunications and storage systems. Data centers typically use large amounts of power, which is supplied by generators that run on diesel fuel. These generators act as a backup power source in case of a power outage or other emergencies.

Why is Fuel Quality Important in Data Centers?

Fuel quality is essential for ensuring the proper operation of backup generators in data centers. Diesel fuel that is contaminated with water, sediment, or other contaminants can cause engine problems, leading to equipment failure, downtime, and costly repairs. In extreme cases, contaminated fuel can even cause generators to fail to start when they are needed most, leaving data centers without backup power during an emergency.

Fuel Polishing: Ensuring Clean Fuel for Critical Operations

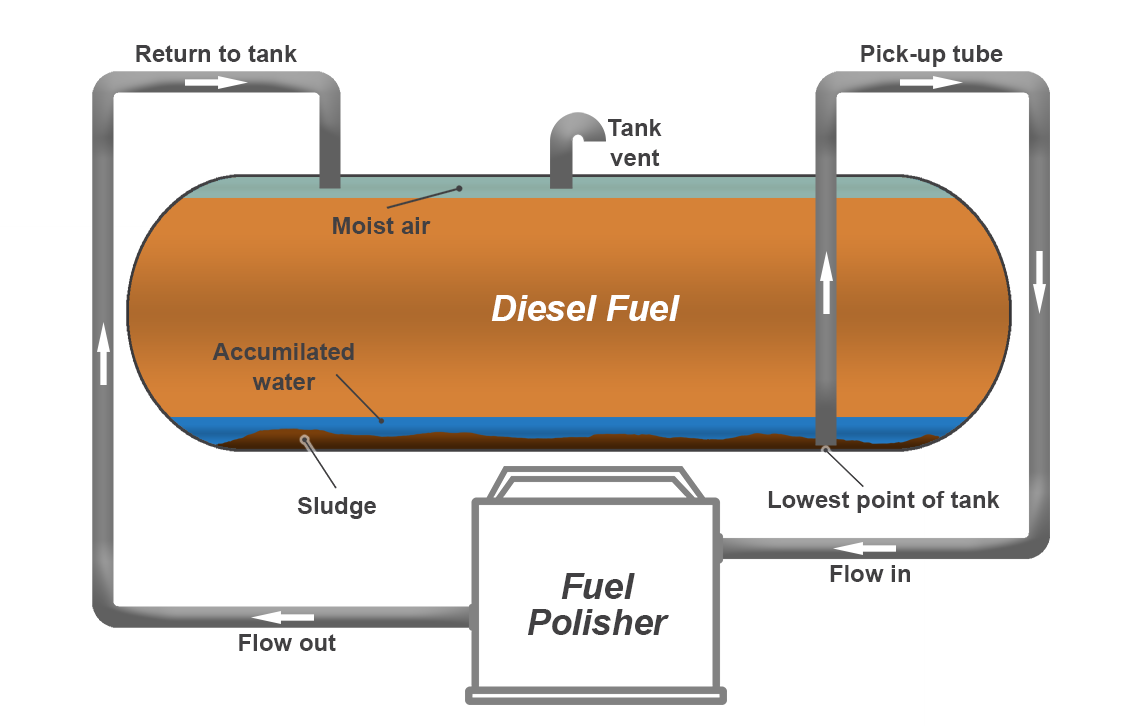

Fuel polishing is the process of removing water, sediment, and other contaminants from diesel fuel. This process involves circulating the fuel through a series of filters and separators, which remove impurities from the fuel. Fuel polishing is a critical component of ensuring that backup generators in data centers have clean and usable fuel.

Fuel polishing typically involves the use of specialized equipment, such as fuel polishing systems, that are designed specifically for this purpose. These systems use a combination of filters, separators, and other technologies to remove impurities from the fuel. They can be installed either as a permanent system or as a portable system that can be brought on-site when needed.

Benefits of Fuel Polishing in Data Centers

The benefits of fuel polishing in data centers are significant. By ensuring that backup generators have clean and usable fuel, data center operators can minimize downtime and equipment failure. This, in turn, helps to maintain the reliability and uptime of critical IT systems and services.

Fuel polishing also helps to extend the life of backup generators and other equipment. Diesel fuel that is contaminated with water, sediment, or other contaminants can cause corrosion and other damage to engine components over time. By removing these impurities from the fuel, fuel polishing helps to extend the life of backup generators and other equipment, reducing the need for costly repairs and replacements.

Conclusion

Data centers are critical to the functioning of our digital world. The reliable operation of these facilities depends on the proper functioning of backup generators, which, in turn, depends on the quality of the fuel used to power them. Fuel polishing is a critical component of ensuring that backup generators have clean and usable fuel, which helps to minimize downtime, reduce equipment failure, and extend the life of critical equipment. By investing in fuel polishing systems and other technologies, data center operators can ensure the reliability and uptime of critical IT systems and services.

Write a Comment