Professional Diesel Fuel Maintenance

Any industry that relies on diesel fuel for its emergency power system wants to keep its fuel tank and engine systems running smoothly. Therefore, regular professional diesel fuel maintenance is a must. This is especially true for stored fuel. And after the fuel has been filtered and cleaned, you want to keep it that way. Hence, having a scheduled periodic servicing is the best way to go.

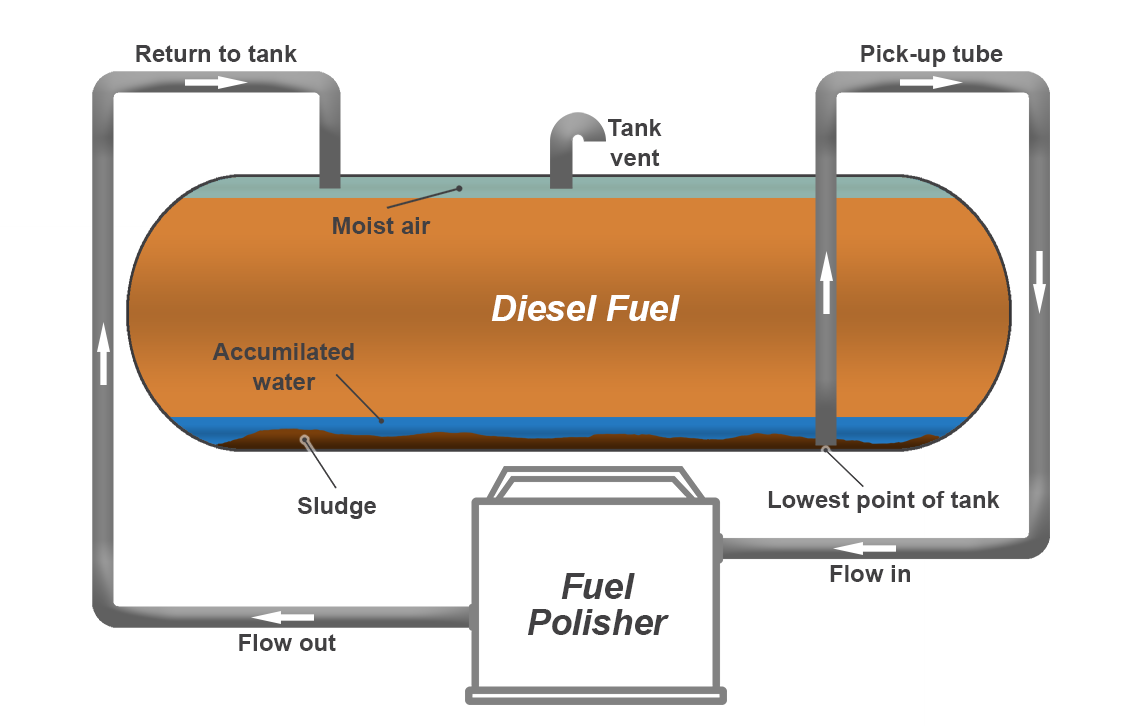

When diesel fuel is stored for more than a year, it’s quality deteriorates. That’s because of the accumulated fuel contaminants due to oxidation. Contaminated fuel has a high potential for causing engine failure. Meanwhile, high capacity fuel tanks that are most often used by different industries need periodic draining and fresh fuel replacement. If draining isn’t an option to prevent stoppage on operations, fuel polishing is highly recommended to clean the stored fuel.

Universal Fuel Polishing & Tank Services is the leading fuel maintenance company based in Colorado. We provide fuel maintenance plans for all of Colorado and Wyoming. We offer annual service contracts and periodic maintenance schedules because we want to take the guesswork out of your system servicing. We handle everything — we give you the data and perform quick tests on your fuel. We do this to assure you that your fuel and engine systems are operating at optimal capacity.

Whether you are a Chief Engineer overseeing an entire power unit in a data center or you’re a long-haul truck driver who wants to get the most out of their mileage, we’re here to help. Choose from Universal Fuel Polishing & Tank Services'

regular fuel maintenance plans to ensure that your fuel is clean and efficient. We eliminate any potential problems regarding your fuel and tank systems before they turn into major issues and cause your engine systems to fail. We utilize proprietary equipment, specialized skills, and years of experience. That is why we have earned the reputation as the

most trusted in fuel maintenance throughout the Rocky Mountain Region.

Why Fuel Tank Maintenance is Crucial?

Maintaining the best condition of your fuel tank is vital to successfully storing diesel fuel. It is necessary to make sure the fuel you store does not go “bad,” which leads to wasting your investment. In addition, you prevent “bad fuel” from entering your power system or equipment. That is why keeping your diesel fuel tank well-maintained ensures optimal performance while it prevents any costly damage to your equipment.

Benefits of Having a Scheduled Fuel Tank Maintenance

- Better fuel economy

- Higher power reliability

- Longer life engine system

- Much Improved safety

- Reduced power downtime

- Reduced injector failures

- Reduced smoke for easy compliance with emission regulations

- Reduced downtime and operational costs

- Short-term and long-term savings

Universal Fuel Polishing & Tank Services specialize in professional diesel fuel tank cleaning. We offer scheduled periodic and annual service contracts for diesel fuel tank maintenance. Talk to one of our fuel experts today to schedule a site visit and detailed analysis.

State-of-the-Art Fuel Tank Cleaning

Dealing with diesel fuel concerns is a universal issue. There is a need for proper cleaning, testing, and maintenance so that your fuel and fuel tank function properly, especially when you need them to. At Universal Fuel Polishing & Tank Services, we begin the process by assessing the sub-base and above, below-ground fuel tanks. Then we keep complete records on every tank, including tech notes and images. When a fuel tank cleaning service is performed on your system, complete documentation from our tech is provided before the job is considered complete.

We at Universal Fuel Polishing & Tank Services are your partner in compliance with the recommendations by the JCAHO, NFPA, and ISO. We are the leading emergency backup generator fuel tank cleaning company. We go above and beyond with diesel fuel tank cleaning. We work directly with chemists, contractors, engineers, and equipment manufacturers and offer the best maintenance and material plans for your facility fuel system. Talk to one of our fuel experts today to schedule a site visit and detailed analysis.

Universal Fuel Polishing & Tank Services of Denver, CO — At Your Service!